Deploy a predictive upkeep answer for airport baggage dealing with methods with Amazon Lookout for Tools

It is a visitor submit co-written with Moulham Zahabi from Matarat.

In all probability everybody has checked their baggage when flying, and waited anxiously for his or her baggage to seem on the carousel. Profitable and well timed supply of your baggage depends upon an enormous infrastructure referred to as the bags dealing with system (BHS). This infrastructure is likely one of the key capabilities of profitable airport operations. Efficiently dealing with baggage and cargo for departing and arriving flights is essential to make sure buyer satisfaction and ship airport operational excellence. This perform is closely depending on the continual operation of the BHS and the effectiveness of upkeep operations. Because the lifeline of the airports, a BHS is a linear asset that may exceed 34,000 meters in size (for a single airport) dealing with over 70 million baggage yearly, making it one of the crucial complicated automated methods and an important element of airport operations.

Unplanned downtime of a baggage dealing with system, whether or not be it a conveyor belt, carousel, or sorter unit, can disrupt airport operations. Such disruption is sure to create an disagreeable passenger expertise and presumably impose penalties on airport service suppliers.

The prevalent problem with sustaining a baggage dealing with system is how one can function an built-in system of over 7,000 property and over 1,000,000 setpoints constantly. These methods additionally deal with thousands and thousands of baggage in several sizes and shapes. It’s protected to imagine that baggage dealing with methods are susceptible to error. As a result of the weather perform in a closed loop, if one factor breaks down, it impacts the whole line. Conventional upkeep actions depend on a large workforce distributed throughout key places alongside the BHS dispatched by operators within the occasion of an operational fault. Upkeep groups additionally rely closely on provider suggestions to schedule downtime for preventive upkeep. Figuring out if preventive upkeep actions are correctly applied or monitoring the efficiency of this sort of asset could also be unreliable and doesn’t scale back the danger of unanticipated downtime.

Spare components administration is an extra problem as lead instances are rising on account of world provide chain disruptions, but stock replenishment choices are primarily based on historic developments. As well as, these developments don’t incorporate the risky dynamic surroundings of working BHS property as they age. To deal with these challenges, a seismic shift must occur in upkeep methods—transferring from a reactive to proactive mindset. This shift requires operators to make the most of the newest know-how to streamline upkeep actions, optimize operations, and reduce working bills.

On this submit, we describe how AWS Associate Airis Options used Amazon Lookout for Equipment, AWS Web of Issues (IoT) providers, and CloudRail sensor applied sciences to offer a state-of-the-art answer to deal with these challenges.

Baggage dealing with system overview

The next diagram and desk illustrate the measurements taken throughout a typical carousel in King Khalid Worldwide Airport in Riyadh.

Information is collected on the completely different places illustrated within the diagram.

| Sensor Kind | Enterprise worth | Datasets | Location |

| IO Hyperlink Velocity Sensors | Homogeneous Carousel Velocity | PDV1 (1 per min) | C |

|

Vibration Sensor with Built-in Temperature Sensor |

Unfastened Screw, Shaft Misaligned, Bearing Injury, Motor Winding Injury |

Fatigue (v-RMS) (m/s) Influence (a-Peak) (m/s^2) Friction (a-RMS) (m/s^2) Temperature (C) Crest |

A and B |

| Distance PEC Sensor | Baggage Throughput | Distance (cm) | D |

The next photos present the surroundings and monitoring gear for the assorted measurements.

Vibration sensor mounted on one of many conveyor motors |

Proximity probe measuring carousel velocity |

|

Line of sight of the bags throughput counter (utilizing a distance sensor) |

Thermal picture of one of many conveyor motors |

|

Resolution overview

The predictive upkeep system (PdMS) for bags dealing with methods is a reference structure that aids airport upkeep operators of their journey to have knowledge as an enabler in enhancing unplanned downtime. It incorporates constructing blocks to speed up the event and deployment of related sensors and providers. The PdMS contains AWS providers to securely handle the lifecycle of edge compute units and BHS property, cloud knowledge ingestion, storage, machine studying (ML) inference fashions, and enterprise logic to energy proactive gear upkeep within the cloud.

This structure was constructed from classes discovered whereas working with airport operations over a number of years. The proposed answer was developed with the help of Northbay Options, an AWS Premier Associate, and will be deployed to airports of all sizes and scales to 1000’s of related units inside 90 days.

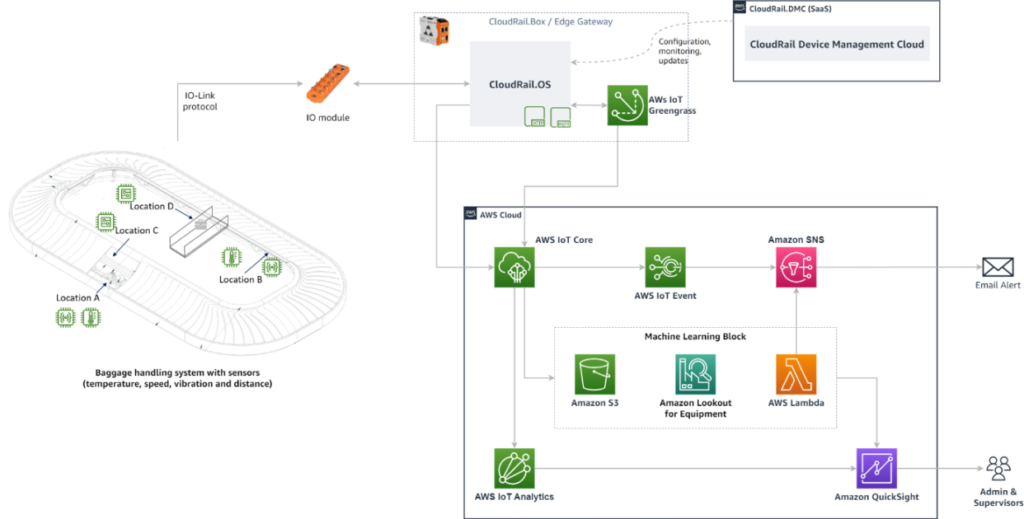

The next structure diagram exposes the underlying parts used to construct the predictive upkeep answer:

We use the next providers to assemble our structure:

- CloudRail.DMC is a software program as a service (SaaS) answer by the German IoT skilled CloudRail GmbH. This group manages fleets of worldwide distributed edge gateways. With this service, industrial sensors, sensible meters, and OPC UA servers will be related to an AWS knowledge lake with just some clicks.

- AWS IoT Core helps you to join billions of IoT units and route trillions of messages to AWS providers with out managing infrastructure. It securely transmits messages to and from your whole IoT units and functions with low latency and excessive throughput. We use AWS IoT Core to connect with the CloudRail sensors and ahead their measurements to the AWS Cloud.

- AWS IoT Analytics is a totally managed service that makes it simple to run and operationalize subtle analytics on large volumes of IoT knowledge with out having to fret about the fee and complexity sometimes required to construct an IoT analytics platform. It’s a straightforward option to run analytics on IoT knowledge to realize correct insights.

- Amazon Lookout for Equipment analyzes knowledge from gear sensors to create an ML mannequin mechanically on your gear primarily based on asset particular knowledge—no knowledge science abilities mandatory. Lookout for Tools analyzes incoming sensor knowledge in actual time and precisely identifies early warning indicators that might result in surprising downtime.

- Amazon QuickSight permits everybody within the group to know the information by asking questions in pure language, visualizing data by interactive dashboards, and mechanically in search of patterns and outliers powered by ML.

As illustrated within the following diagram, this structure permits sensor knowledge to circulation to operational insights.

Information factors are collected utilizing IO-Hyperlink sensors: IO-Hyperlink is a standardized interface to allow seamless communication from the management stage of an industrial asset (in our case, the bags dealing with system) to the sensor stage. This protocol is used to feed sensor knowledge right into a CloudRail edge gateway and loaded into AWS IoT Core. The latter then offers gear knowledge to ML fashions to establish operational and gear points that can be utilized to find out optimum timing for asset upkeep or substitute with out incurring pointless prices.

Information assortment

Retrofitting present property and their controls methods to the cloud stays a difficult strategy for operators of kit. Including secondary sensors offers a quick and safe option to purchase the mandatory knowledge whereas not interfering with present methods. Subsequently, it’s simpler, quicker, and non-invasive in comparison with the direct connection of a machine’s PLCs. Moreover, retrofitted sensors will be chosen to exactly measure the information factors required for particular failure modes.

With CloudRail, each industrial IO-Hyperlink sensor will be related to AWS providers like AWS IoT Core, AWS IoT SiteWise, or AWS IoT Greengrass inside just a few seconds by a cloud-based machine administration portal (CloudRail.DMC). This permits IoT specialists to work from centralized places and onboard bodily methods which are globally distributed. The answer solves the challenges of knowledge connectivity for predictive upkeep methods by a straightforward plug-and-play mechanism.

The gateway acts because the Industrial Demilitarized Zone (IDMZ) between the gear (OT) and the cloud service (IT). By way of an built-in fleet administration software, CloudRail ensures that the newest safety patches are rolled out mechanically to 1000’s of installations.

The next picture exhibits an IO-Hyperlink sensor and the CloudRail edge gateway (in orange):

Coaching an anomaly detection mannequin

Organizations from most industrial segments see fashionable upkeep methods transferring away from the run-to-failure, reactive approaches and progressing in direction of extra predictive strategies. Nonetheless, transferring to a condition-based or predictive upkeep strategy requires knowledge collected from sensors put in all through services. Utilizing historic knowledge captured by these sensors along side analytics helps establish precursors to gear failures, which permits upkeep personnel to behave accordingly earlier than breakdown.

Predictive upkeep methods depend on the potential to establish when failures may happen. Tools OEMs normally present datasheets for his or her gear and advocate monitoring sure operational metrics primarily based on near-perfect situations. Nonetheless, these situations are hardly ever real looking due to the pure put on of the asset, the environmental situations it operates in, its previous upkeep historical past, or simply the best way it’s worthwhile to function it to attain what you are promoting outcomes. As an example, two an identical motors (make, mannequin, manufacturing date) had been put in in the identical carousel for this proof of idea. These motors operated at completely different temperature ranges on account of completely different climate publicity (one a part of the conveyor belt on the within and the opposite outdoors of the airport terminal).

Motor 1 operated in a temperature starting from 32–35°C. Vibration velocity RMS can change on account of motor fatigue (for instance, alignment errors or imbalance issues). As proven within the following determine, this motor exhibits fatigue ranges ranging between 2–6, with some peaks at 9.

Motor 2 operated in a cooler surroundings, the place the temperature was ranging between 20–25°C. On this context, motor 2 exhibits fatigue ranges between 4–8, with some peaks at 10:

Most ML approaches count on very particular area data and data (usually troublesome to acquire) that have to be extracted from the best way you use and keep every asset (for instance, failure degradation patterns). This work must be carried out every time you wish to monitor a brand new asset, or if the asset situations change considerably (resembling once you exchange an element). Which means that an amazing mannequin delivered on the prototyping section will seemingly see a efficiency hit when rolled out on different property, drastically lowering the accuracy of the system and in the long run, dropping the end-users’ confidence. This may occasionally additionally trigger many false positives, and also you would want the talents mandatory to seek out your legitimate indicators in all of the noise.

Lookout for Tools solely analyzes your time collection knowledge to be taught the traditional relationships between your indicators. Then, when these relationships begin to deviate from the traditional working situations (captured at coaching state), the service will flag the anomaly. We discovered that strictly utilizing historic knowledge for every asset helps you to give attention to applied sciences that may be taught the working situations that will likely be distinctive to a given asset within the very surroundings it’s working in. This allows you to ship predictions supporting root trigger evaluation and predictive upkeep practices at a granular, per-asset stage and macro stage (by assembling the suitable dashboard to allow you to get an outline of a number of property directly). That is the strategy we took and the explanation we determined to make use of Lookout for Tools.

Coaching technique: Addressing the chilly begin problem

The BHS we focused wasn’t instrumented at first. We put in CloudRail sensors to begin accumulating new measurements from our system, however this meant we solely had a restricted historic depth to coach our ML mannequin. We addressed the chilly begin problem on this case by recognizing that we’re constructing a constantly enhancing system. After the sensors had been put in, we collected an hour of knowledge and duplicated this data to begin utilizing Lookout for Tools as quickly as potential and take a look at our total pipeline.

As anticipated, the primary outcomes had been fairly unstable as a result of the ML mannequin was uncovered to a really small interval of operations. This meant that any new conduct not seen throughout the first hour can be flagged. When trying on the top-ranking sensors, the temperature on one of many motors appeared to be the primary suspect (T2_MUC_ES_MTRL_TMP in orange within the following determine). As a result of the preliminary knowledge seize was very slim (1 hour), over the course of the day, the primary change was coming from the temperature values (which is in keeping with the environmental situations at the moment).

When matching this with the environmental situations round this particular conveyor belt, we confirmed that the surface temperature elevated severely, which, in flip, elevated the temperature measured by this sensor. On this case, after the brand new knowledge (accounting for the surface temperature improve) is included into the coaching dataset, it will likely be a part of the traditional conduct as captured by Lookout for Tools and related conduct sooner or later will likely be much less prone to elevate any occasions.

After 5 days, the mannequin was retrained and the false optimistic charges instantly fell drastically:

Though this chilly begin downside was an preliminary problem to acquire actionable insights, we used this chance to construct a retraining mechanism the end-user can set off simply. A month into the experimentation, we skilled a brand new mannequin by duplicating a month’s price of sensor knowledge into 3 months. This continued to scale back the false optimistic charges because the mannequin was uncovered to a broader set of situations. An analogous false optimistic fee drop occurred after this retraining: the situation modeled by the system was nearer to what customers are experiencing in actual life. After 3 months, we lastly had a dataset that we may use with out utilizing this duplication trick.

Any more, we’ll launch a retraining each 3 months and, as quickly as potential, will use as much as 1 yr of knowledge to account for the environmental situation seasonality. When deploying this method on different property, we will reuse this automated course of and use the preliminary coaching to validate our sensor knowledge pipeline.

After the mannequin was skilled, we deployed the mannequin and began sending stay knowledge to Lookout for Tools. Lookout for Tools helps you to configure a scheduler that wakes up often (for instance, each hour) to ship recent knowledge to the skilled mannequin and acquire the outcomes.

Now that we all know how one can prepare, enhance, and deploy a mannequin, let’s take a look at the operational dashboards applied for the end-users.

Information visualization and insights

Finish-users want a option to extract extra worth from their operational knowledge to higher enhance their asset utilization. With QuickSight, we related the dashboard to the uncooked measurement knowledge supplied by our IoT system, permitting customers to check and distinction key items of kit on a given BHS.

Within the following dashboard, customers can verify the important thing sensors used to watch the situation of the BHS and procure period-over-period metrics modifications.

Within the previous plot, customers can visualize any surprising imbalance of the measurement for every motor (left and proper plots for temperature, fatigue, vibration, friction, and impression). On the backside, key efficiency indicators are summarized, with forecast and period-over-period developments referred to as out.

Finish-users can entry data for the next functions:

- View historic knowledge in intervals of two hours as much as 24 hours.

- Extract uncooked knowledge by way of CSV format for exterior integration.

- Visualize asset efficiency over a set time frame.

- Produce insights for operational planning and enhance asset utilization.

- Carry out correlation evaluation. Within the following plot, the person can visualize a number of measurements (resembling motor fatigue vs. temperature, or baggage throughput vs. carousel velocity) and use this dashboard to higher inform the following finest upkeep motion.

Eliminating noise from the information

After just a few weeks, we seen that Lookout for Tools was emitting some occasions regarded as false positives.

When analyzing these occasions, we found irregular drops within the velocity of the carousel motor.

We met with the upkeep group and so they knowledgeable us these stops had been both emergency stops or deliberate downtime upkeep actions. With this data, we labeled the emergency stops as anomalies and fed them to Lookout for Tools, whereas the deliberate downtimes had been thought-about regular conduct for this carousel.

Understanding such eventualities the place irregular knowledge will be influenced by managed exterior actions is essential to enhance the anomaly detection mannequin accuracy over time.

Smoke testing

After just a few hours from retraining the mannequin and attaining comparatively no anomalies, our group bodily harassed the property, which was instantly detected by the system. It is a frequent request from customers as a result of they should familiarize themselves with the system and the way it reacts.

We constructed our dashboard to permit end-users to visualise historic anomalies with a limiteless interval. Utilizing a enterprise intelligence service allow them to arrange their knowledge at will, and we’ve discovered that bar charts over a 24-hour interval or pie charts are one of the simplest ways to get view of the situation of the BHS. Along with the dashboards that customers can view each time they want, we arrange automated alerts despatched to a delegated electronic mail tackle and by way of textual content message.

Extracting deeper insights from anomaly detection fashions

Sooner or later, we intend to extract deeper insights from the anomaly detection fashions skilled with Lookout for Tools. We are going to proceed to make use of QuickSight to construct an expanded set of widgets. As an example, we’ve discovered that the information visualization widgets uncovered within the GitHub samples for Lookout for Equipment permit us to extract much more insights from the uncooked outputs of our fashions.

Outcomes

Reactive upkeep in baggage dealing with methods interprets to the next:

- Decrease passenger satisfaction on account of prolonged wait instances or broken baggage

- Decrease asset availability because of the unplanned failures and stock scarcity of essential spare components

- Increased working bills on account of rising stock ranges along with increased upkeep prices

Evolving your upkeep technique to include dependable, predictive analytics into the cycle of decision-making goals to enhance asset operation and assist keep away from compelled shutdowns.

The monitoring gear was put in regionally in 1 day and configured utterly remotely by IoT specialists. The cloud structure described within the answer overview was then efficiently deployed inside 90 days. A quick implementation time proves the advantages proposed to the end-user, rapidly resulting in a shift in upkeep technique from human-based reactive (fixing breakdowns) to machine-based, data-driven proactive (stopping downtimes).

Conclusion

The cooperation between Airis, CloudRail, Northbay Options, and AWS led to new achievement on the King Khalid Worldwide Airport (see the press release for extra particulars). As a part of their digital transformation technique, the Riyadh Airport plans on additional deployments to cowl different electro-mechanical methods like passenger boarding bridges and HVAC methods.

When you have feedback about this submit, please submit them within the feedback part. When you have questions on this answer or its implementation, please begin a brand new thread on re:Post, the place AWS specialists and the broader neighborhood can help you.

In regards to the authors

Moulham Zahabi is an aviation specialist with over 11 years of expertise in designing and managing aviation tasks, and managing essential airport property within the GCC area. He’s additionally one of many co-founders of Airis-Options.ai, which goals to steer the aviation business’s digital transformation by modern AI/ML options for airports and logistical facilities. Immediately, Moulham is heading the Asset Administration Directorate within the Saudi Civil Aviation Holding Firm (Matarat).

Moulham Zahabi is an aviation specialist with over 11 years of expertise in designing and managing aviation tasks, and managing essential airport property within the GCC area. He’s additionally one of many co-founders of Airis-Options.ai, which goals to steer the aviation business’s digital transformation by modern AI/ML options for airports and logistical facilities. Immediately, Moulham is heading the Asset Administration Directorate within the Saudi Civil Aviation Holding Firm (Matarat).

Fauzan Khan is a Senior Options Architect working with public sector prospects, offering steering to design, deploy, and handle their AWS workloads and architectures. Fauzan is obsessed with serving to prospects undertake modern cloud applied sciences within the space of HPC and AI/ML to deal with enterprise challenges. Outdoors of labor, Fauzan enjoys spending time in nature.

Fauzan Khan is a Senior Options Architect working with public sector prospects, offering steering to design, deploy, and handle their AWS workloads and architectures. Fauzan is obsessed with serving to prospects undertake modern cloud applied sciences within the space of HPC and AI/ML to deal with enterprise challenges. Outdoors of labor, Fauzan enjoys spending time in nature.

Michaël Hoarau is an AI/ML Specialist Options Architect at AWS who alternates between knowledge scientist and machine studying architect, relying on the second. He’s obsessed with bringing the AI/ML energy to the store flooring of his industrial prospects and has labored on a variety of ML use instances, starting from anomaly detection to predictive product high quality or manufacturing optimization. He revealed a book on time series analysis in 2022 and often writes about this matter on LinkedIn and Medium. When not serving to prospects develop the following finest machine studying experiences, he enjoys observing the celebrities, touring, or enjoying the piano.

Michaël Hoarau is an AI/ML Specialist Options Architect at AWS who alternates between knowledge scientist and machine studying architect, relying on the second. He’s obsessed with bringing the AI/ML energy to the store flooring of his industrial prospects and has labored on a variety of ML use instances, starting from anomaly detection to predictive product high quality or manufacturing optimization. He revealed a book on time series analysis in 2022 and often writes about this matter on LinkedIn and Medium. When not serving to prospects develop the following finest machine studying experiences, he enjoys observing the celebrities, touring, or enjoying the piano.