HAYAT HOLDING makes use of Amazon SageMaker to extend product high quality and optimize manufacturing output, saving $300,000 yearly

It is a visitor submit by Neslihan Erdogan, World Industrial IT Supervisor at HAYAT HOLDING.

With the continued digitization of the manufacturing processes and Trade 4.0, there’s huge potential to make use of machine studying (ML) for high quality prediction. Course of manufacturing is a manufacturing technique that makes use of formulation or recipes to supply items by combining substances or uncooked supplies.

Predictive high quality contains using ML strategies in manufacturing to estimate and classify product-related high quality primarily based on manufacturing course of information with the next targets[1]:

- High quality description – The identification of relationships between course of variables and product high quality. For example, how does the quantity of an adhesive ingredient impact the standard parameters, corresponding to its energy and elasticity.

- High quality prediction – The estimation of a high quality variable on the premise of course of variables for resolution assist or for automation. For instance, how a lot kg/m3 adhesive ingredient shall be ingested to realize sure energy and elasticity.

- High quality classification – Along with high quality prediction, this entails estimation of sure product high quality varieties.

On this submit, we share how HAYAT HOLDING—a worldwide participant with 41 firms working in several industries, together with HAYAT, the world’s fourth-largest branded diaper producer, and KEAS, the world’s fifth-largest wood-based panel producer—collaborated with AWS to construct an answer that makes use of Amazon SageMaker Mannequin Coaching, Amazon SageMaker Automated Mannequin Tuning, and Amazon SageMaker Mannequin Deployment to repeatedly enhance operational efficiency, improve product high quality, and optimize manufacturing output of medium-density fiberboard (MDF) wooden panels.

Product high quality prediction and adhesive consumption advice outcomes will be noticed by subject consultants by means of dashboards in near-real time, leading to a sooner suggestions loop. Laboratory outcomes point out a major affect equating to financial savings of $300,000 yearly, decreasing their carbon footprint in manufacturing by stopping pointless chemical waste.

ML-based predictive high quality in HAYAT HOLDING

HAYAT is the world’s fourth-largest branded child diapers producer and the biggest paper tissue producer of the EMEA. KEAS (Kastamonu Entegre Ağaç Sanayi) is a subsidy of HAYAT HOLDING, for manufacturing within the wood-based panel {industry}, and is positioned because the fourth in Europe and the fifth on this planet.

Medium-density fiberboard (MDF) is an engineered wooden product made by breaking down wooden residuals into fibers, combining it with adhesives, and forming it into panels by making use of excessive temperature and stress. It has many utility areas corresponding to furnishings, cabinetry, and flooring.

Manufacturing of MDF wooden panels requires intensive use of adhesives (double-digit tons consumed every year at HAYAT HOLDING).

In a typical manufacturing line, tons of of sensors are used. Product high quality is recognized by tens of parameters. Making use of the right quantity of adhesives is a vital price merchandise in addition to an essential high quality issue for the produced panel, corresponding to density, screw holding capacity, tensile energy, modulus elasticity, and bending energy. Whereas extreme use of glue will increase manufacturing prices redundantly, poor utilization of glue raises high quality issues. Incorrect utilization causes as much as tens of 1000’s of {dollars} in a single shift. The problem is that there’s a regressive dependency of high quality on the manufacturing course of.

Human operators resolve on the quantity of glue for use primarily based on area experience. This know-how is solely empirical and takes years of experience to construct competence. To assist the decision-making for the human operator, laboratory exams are carried out on chosen samples to exactly measure high quality throughout manufacturing. The lab outcomes present suggestions to the operators revealing product high quality ranges. Nonetheless, lab exams will not be in actual time and are utilized with a delay of as much as a number of hours. The human operator makes use of lab outcomes to step by step modify glue consumption to realize the required high quality threshold.

Overview of resolution

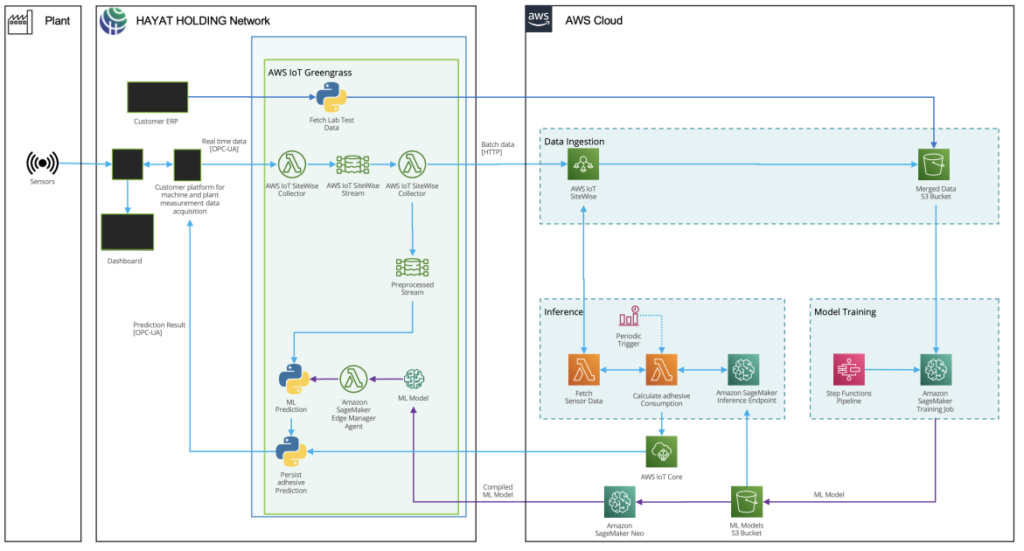

High quality prediction utilizing ML is highly effective however requires effort and ability to design, combine with the manufacturing course of, and preserve. With the assist of AWS Prototyping specialists, and AWS Accomplice Deloitte, HAYAT HOLDING constructed an end-to-end pipeline as follows:

- Ingest sensor information from manufacturing plant to AWS

- Carry out information preparation and ML mannequin era

- Deploy fashions on the edge

- Create operator dashboards

- Orchestrate the workflow

The next diagram illustrates the answer structure.

Information ingestion

HAYAT HOLDING has a state-of-the artwork infrastructure for buying, recording, analyzing, and processing measurement information.

Two varieties of information sources exist for this use case. Course of parameters are set for the manufacturing of a selected product and are often not modified throughout manufacturing. Sensor information is taken in the course of the manufacturing course of and represents the precise situation of the machine.

Enter information is streamed from the plant by way of OPC-UA by means of SiteWise Edge Gateway in AWS IoT Greengrass. In complete, 194 sensors have been imported and used to extend the accuracy of the predictions.

Mannequin coaching and optimization with SageMaker automated mannequin tuning

Previous to the mannequin coaching, a set of information preparation actions are carried out. For example, an MDF panel plant produces a number of distinct merchandise on the identical manufacturing line (a number of varieties and sizes of wooden panels). Every batch is related to a distinct product, with totally different uncooked supplies and totally different bodily traits. Though the gear and course of time collection are recorded repeatedly and will be seen as a single-flow time collection listed by time, they should be segmented by the batch they’re related to. For example, in a shift, product panels could also be produced for various durations. A pattern of the produced MDF is shipped to the laboratory for high quality exams occasionally. Different function engineering duties embrace function discount, scaling, unsupervised dimensionality discount utilizing PCA (Principal Element Evaluation), function significance, and outlier detection.

After the information preparation part, a two-stage method is used to construct the ML fashions. Lab check samples are performed by intermittent random product sampling from the conveyor belt. Samples are despatched to a laboratory for high quality exams. As a result of the lab outcomes can’t be introduced in actual time, the suggestions loop is comparatively gradual. The primary mannequin is skilled to foretell lab outcomes for product high quality parameters: density, elasticity, pulling resistance, swelling, absorbed water, floor sturdiness, moisture, floor suction, and bending resistance. The second mannequin is skilled to suggest the quantity of glue for use in manufacturing, relying on the expected output high quality.

Establishing and managing customized ML environments will be time-consuming and cumbersome. Amazon SageMaker offers a collection of built-in algorithms, pre-trained fashions, and pre-built resolution templates to assist information scientists and ML practitioners get began on coaching and deploying ML fashions shortly.

A number of ML fashions have been skilled utilizing SageMaker built-in algorithms for the highest N most produced product varieties and for various high quality parameters. The standard prediction fashions determine the relationships between glue utilization and 9 high quality parameters. The advice fashions predict the minimal glue utilization to fulfill high quality necessities utilizing the next method: an algorithm begins from the best allowed glue quantity and reduces it step-by-step if all necessities are happy till the minimal quantity of glue allowed. If the max quantity of glue doesn’t fulfill all the necessities, it offers an error.

SageMaker automated mannequin tuning, also referred to as hyperparameter tuning, finds the perfect model of a mannequin by operating many coaching jobs in your dataset utilizing the algorithm and ranges of hyperparameters that you simply specify. It then chooses the hyperparameter values that lead to a mannequin that performs the perfect, as measured by a metric that you simply select.

With automated mannequin tuning, the workforce centered on defining the appropriate goal, scoping the hyperparameters and the search house. Automated mannequin tuning takes care of the remaining, together with the infrastructure, operating and orchestrating coaching jobs in parallel, and bettering hyperparameter choice. Automated mannequin tuning offers a variety of coaching occasion varieties. The mannequin was fine-tuned on c5.x2large occasion varieties utilizing an clever model of hyperparameter tuning strategies that’s primarily based on the Bayesian search idea and is designed to search out the perfect mannequin within the shortest time.

Inference on the edge

A number of strategies can be found for deploying ML fashions to get predictions.

SageMaker real-time inference is good for workloads the place then are real-time, interactive, low-latency necessities. Throughout the prototyping part, HAYAT HOLDING deployed fashions to SageMaker internet hosting providers and acquired endpoints which might be totally managed by AWS. SageMaker multi-model endpoints present a scalable and cost-effective resolution for deploying massive numbers of fashions. They use the identical fleet of assets and a shared serving container to host all of your fashions. This reduces internet hosting prices by bettering endpoint utilization in contrast with utilizing single-model endpoints. It additionally reduces deployment overhead as a result of SageMaker manages loading fashions in reminiscence and scaling them primarily based on the site visitors patterns to your endpoint.

SageMaker real-time inference is used with multi-model endpoints for price optimization and for making all fashions obtainable always throughout growth. Though utilizing an ML mannequin for every product kind leads to larger inference accuracy, the price of growing and testing these fashions will increase accordingly, and it additionally turns into troublesome to handle a number of fashions. SageMaker multi-model endpoints deal with these ache factors and provides the workforce a speedy and cost-effective resolution to deploy a number of ML fashions.

Amazon SageMaker Edge offers mannequin administration for edge units so you may optimize, safe, monitor, and preserve ML fashions on fleets of edge units. Working ML fashions on edge units is difficult, as a result of units, not like cloud cases, have restricted compute, reminiscence, and connectivity. After the mannequin is deployed, it’s essential repeatedly monitor the fashions, as a result of mannequin drift may cause the standard of mannequin to decay extra time. Monitoring fashions throughout your system fleets is troublesome as a result of it’s essential write customized code to gather information samples out of your system and acknowledge skew in predictions.

For manufacturing, the SageMaker Edge Supervisor agent is used to make predictions with fashions loaded onto an AWS IoT Greengrass system.

Conclusion

HAYAT HOLDING was evaluating a complicated analytics platform as a part of their digital transformation technique and needed to carry AI to the group for high quality prediction in manufacturing.

With the assist of AWS Prototyping specialists and AWS Accomplice Deloitte, HAYAT HOLDING constructed a novel information platform structure and an ML pipeline to deal with long-term enterprise and technical wants.

HAYAT KIMYA built-in the ML resolution in certainly one of its vegetation. Laboratory outcomes point out a major affect equating to financial savings of $300,000 yearly, decreasing their carbon footprint in manufacturing by stopping pointless chemical waste. The answer offers a sooner suggestions loop to the human operators by presenting product high quality predictions and adhesive consumption advice outcomes by means of dashboards in near-real time. The answer will ultimately be deployed throughout HAYAT HOLDING’s different wooden panel vegetation.

ML is a extremely iterative course of; over the course of a single venture, information scientists practice tons of of various fashions, datasets, and parameters searching for most accuracy. SageMaker affords probably the most full set of instruments to harness the facility of ML. It enables you to arrange, monitor, examine, and consider ML experiments at scale. You possibly can enhance the bottom-line affect of your ML groups to realize vital productiveness enhancements utilizing SageMaker built-in algorithms, automated mannequin tuning, real-time inference, and multi-model endpoints.

Speed up time to outcomes and optimize operations by modernizing your small business method from edge to cloud utilizing Machine Learning on AWS. Benefit from industry-specific improvements and options utilizing AWS for Industrial.

Share your suggestions and questions within the feedback.

About HAYAT HOLDING

HAYAT HOLDING, whose foundations have been laid in 1937, is a worldwide participant immediately, with 41 firms working in several industries, together with HAYAT within the fast-moving shopper items sector, KEAS (Kastamonu Entegre Ağaç Sanayi) within the wood-based panel sector, and LIMAS within the port administration sector, with a workforce of over 17,000 individuals. HAYAT HOLDING delivers 49 manufacturers produced with superior applied sciences in 36 manufacturing amenities in 13 nations to thousands and thousands of shoppers worldwide.

Working within the fast-moving shopper items sector, Hayat was based in 1987. Right this moment, quickly advancing on the trail of globalization with 21 manufacturing amenities in 8 nations all over the world, Hayat is the world’s fourth-largest branded diaper producer and the biggest tissue producer within the Center East, Jap Europe, and Africa, and a significant participant within the fast-moving shopper items sector. With its 16 highly effective manufacturers, together with Molfix, Bebem, Molped, Joly, Bingo, Take a look at, Has, Papia, Familia, Teno, Focus, Nelex, Goodcare, and Evony within the hygiene, house care, tissue, and private well being classes, Hayat brings HAYAT* to thousands and thousands of properties in additional than 100 nations.

Kastamonu Entegre Ağaç Sanayi (KEAS), the primary funding of HAYAT HOLDING in its industrialization transfer, was based in 1969. Persevering with its uninterrupted development in direction of changing into a worldwide energy in its sector, it ranks fourth in Europe and fifth on this planet. KEAS ranks first within the {industry} with its roughly 7,000 staff and exports to greater than 100 nations.

*“Hayat” means “life” in Turkish.

References

- Tercan H, “Machine studying and deep studying primarily based predictive high quality in manufacturing: a scientific evaluation”, Journal of Clever Manufacturing, 2022.

In regards to the authors

Neslihan Erdoğan, (BSc and MSc in Electrical Engineering), held numerous technical & enterprise roles as a specialist, architect and supervisor in Info Applied sciences. She has been working in HAYAT because the World Industrial IT Supervisor and led Trade 4.0, Digital Transformation, OT Safety and Information & AI tasks.

Neslihan Erdoğan, (BSc and MSc in Electrical Engineering), held numerous technical & enterprise roles as a specialist, architect and supervisor in Info Applied sciences. She has been working in HAYAT because the World Industrial IT Supervisor and led Trade 4.0, Digital Transformation, OT Safety and Information & AI tasks.

Çağrı Yurtseven (BSc in Electrical-Electronics Engineering, Bogazici College) is the Enterprise Account Supervisor at Amazon Internet Providers. He’s main Sustainability and Industrial IOT initiatives in Turkey whereas serving to prospects notice their full potential by displaying the artwork of the doable on AWS.

Çağrı Yurtseven (BSc in Electrical-Electronics Engineering, Bogazici College) is the Enterprise Account Supervisor at Amazon Internet Providers. He’s main Sustainability and Industrial IOT initiatives in Turkey whereas serving to prospects notice their full potential by displaying the artwork of the doable on AWS.

Cenk Sezgin (PhD – Electrical Electronics Engineering) is a Principal Supervisor at AWS EMEA Prototyping Labs. He helps prospects with exploration, ideation, engineering and growth of state-of-the-art options utilizing rising applied sciences corresponding to IoT, Analytics, AI/ML & Serverless.

Cenk Sezgin (PhD – Electrical Electronics Engineering) is a Principal Supervisor at AWS EMEA Prototyping Labs. He helps prospects with exploration, ideation, engineering and growth of state-of-the-art options utilizing rising applied sciences corresponding to IoT, Analytics, AI/ML & Serverless.

Hasan-Basri AKIRMAK (BSc and MSc in Pc Engineering and Government MBA in Graduate College of Enterprise) is a Principal Options Architect at Amazon Internet Providers. He’s a enterprise technologist advising enterprise phase purchasers. His space of specialty is designing architectures and enterprise instances on massive scale information processing techniques and Machine Studying options. Hasan has delivered Enterprise growth, Programs Integration, Program Administration for purchasers in Europe, Center East and Africa. Since 2016 he mentored tons of of entrepreneurs at startup incubation applications pro-bono.

Hasan-Basri AKIRMAK (BSc and MSc in Pc Engineering and Government MBA in Graduate College of Enterprise) is a Principal Options Architect at Amazon Internet Providers. He’s a enterprise technologist advising enterprise phase purchasers. His space of specialty is designing architectures and enterprise instances on massive scale information processing techniques and Machine Studying options. Hasan has delivered Enterprise growth, Programs Integration, Program Administration for purchasers in Europe, Center East and Africa. Since 2016 he mentored tons of of entrepreneurs at startup incubation applications pro-bono.

Mustafa Aldemir (BSc in Electrical-Electronics Engineering, MSc in Mechatronics and PhD-candidate in Pc Science) is the Robotics Prototyping Lead at Amazon Internet Providers. He has been designing and growing Web of Issues and Machine Studying options for a few of the greatest prospects throughout EMEA and main their groups in implementing them. In the meantime, he has been delivering AI programs at Amazon Machine Studying College and Oxford College.

Mustafa Aldemir (BSc in Electrical-Electronics Engineering, MSc in Mechatronics and PhD-candidate in Pc Science) is the Robotics Prototyping Lead at Amazon Internet Providers. He has been designing and growing Web of Issues and Machine Studying options for a few of the greatest prospects throughout EMEA and main their groups in implementing them. In the meantime, he has been delivering AI programs at Amazon Machine Studying College and Oxford College.