Ecosystem for 2nm Chip Growth Is Nearing Completion

Talking to companions final week as a part of their annual Open Innovation Platform discussion board in Europe, a giant portion of TSMC’s roadshow was devoted to the subsequent era of the corporate’s foundry know-how. TSMC’s 2 nm-class N2, N2P, and N2X process technologies are set to introduce a number of improvements, together with nanosheet gate-all-around (GAA) transistors, bottom energy supply, and super-high-performance metal-insulator-metal (SHPMIM) capacitor over the subsequent few years. However so as to make the most of these improvements, TSMC warns, chip designers might want to use all-new digital design automation (EDA), simulation, and verification instruments in addition to IP. And whereas making such a giant shift is rarely a straightforward process, TSMC is bringing some excellent news to chip designers early-on: even with N2 nonetheless a few years out, lots of the main EDA instruments, verification instruments, basis IP, and even analog IP for N2 are already obtainable to be used.

“For N2 we could possibly be working with them two years prematurely already as a result of nanosheet is completely different,” stated Dan Kochpatcharin, Head of Design Infrastructure Administration at TSMC, on the OIP 2023 convention in Amsterdam. “[EDA] instruments need to be prepared, so what the OIP did is to work with them early. We’ve an enormous engineering staff to work with the EDA companions, IP companions, [and other] companions.”

| Marketed PPA Enhancements of New Course of Applied sciences Knowledge introduced throughout convention calls, occasions, press briefings and press releases |

|||||

| TSMC | |||||

| N5 vs N7 |

N3 vs N5 |

N3E vs N5 |

N2 vs N3E |

||

| Energy | -30% | -25-30% | -34% | -25-30% | |

| Efficiency | +15% | +10-15% | +18% | +10-15% | |

| Chip Density* | ? | ? | ~1.3X | >1.15X | |

| Quantity Manufacturing |

Q2 2022 | H2 2022 | Q2/Q3 2023 | H2 2025 | |

*Chip density printed by TSMC displays ‘combined’ chip density consisting of fifty% logic, 30% SRAM, and 20% analog.

Preparations for the beginning of N2 chip manufacturing, scheduled for someday within the second half of 2025, started way back. Nanosheet GAA transistors behave otherwise than acquainted FinFETs, so EDA and different software and IP makers needed to construct their merchandise from scratch. That is the place TSMC’s Open Innovation Platform (OIP) demonstrated its prowess and enabled TSMC’s companions to begin engaged on their merchandise nicely prematurely.

By now, main EDA instruments from Cadence and Synopsys in addition to many instruments from Ansys and Siemens EDA have been licensed by TSMC, so chip builders can already use them to design chips. Additionally, EDA software program applications from Cadence and Synopsys are prepared for analog design migration. Moreover, Cadence’s EDA instruments already assist N2P’s bottom energy supply community.

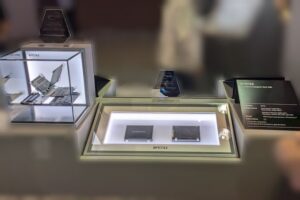

With pre-built IP designs, issues are taking a bit longer. TSMC’s basis libraries and IP, together with commonplace cells, GPIO/ESD, PLL, SRAM, and ROM are prepared each for cell and high-performance computing functions. In the meantime, some PLLs exist in pre-silicon improvement kits, whereas others are silicon confirmed. Lastly, blocks resembling non-volatile reminiscence, interface IP, and even chiplet IP usually are not but obtainable – bottlenecking some chip designs – however these blocks in energetic improvement or deliberate for improvement by firms like Alphawave, Cadence, Credo, eMemory, GUC, and Synopsys, in keeping with a TSMC slide. Finally, the ecosystem of instruments and libraries for designing 2 nm chips is coming collectively, but it surely’s not all there fairly but.

“[Developing IP featuring nanosheet transistors] just isn’t more durable, but it surely does take extra cycle time, cycle time is a bit longer,” stated Kochpatcharin. “A few of these IP distributors additionally should be skilled [because] it’s simply completely different. To go from planar [transistor] to FinFET, just isn’t more durable, you simply have to know easy methods to do the FinFET. [It is] identical factor, you simply have to know easy methods to do [this]. So, it does take some to be skilled, however [when you are trained], it’s simple. So that’s the reason we began early.”

Though lots of the main constructing blocks for chips are N2-ready, quite a lot of work nonetheless needs to be executed by many firms earlier than TSMC’s 2 nm-class course of applied sciences go into mass manufacturing. Massive firms, which are inclined to design (or co-design) IP and improvement instruments themselves are already engaged on their 2 nm chips, and needs to be prepared with their merchandise by the point mass manufacturing begins in 2H 2025. Different gamers can even hearth up their design engines as a result of 2 nm preps are nicely underway at TSMC and its companions.